Orbital UAV is a world-leading developer of integrated heavy fuel engine systems for military and commercial drones. Our innovative propulsion systems enhance UAV flight times and significantly reduce operational costs, enabling global defense forces to efficiently and effectively field the state of the art in unmanned ISR (intelligence, surveillance and reconnaissance) and battlefield logistics.

With 40 years of experience in developing advanced engine solutions, and 15 years of experience as the global leader in spark-ignited heavy fuel propulsion technology, we supply and work closely with the world’s largest developers of tactical UAVs, including Insitu and Textron. Our products have also been utilized for a range of demanding commercial applications including long-range mapping, surveying, and industrial inspection.

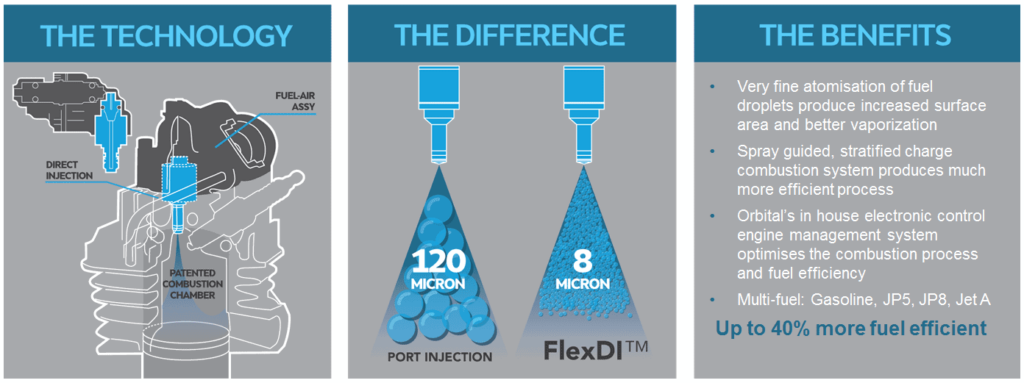

FlexDI

Spark ignition technology for heavy fuel UAV engines

Our spark-ignited heavy fuel engines are based around our proprietary FlexDI technology, featuring a spray-guided direct fuel injection system that utilizes injected air to atomize the fuel. The extremely fine level of atomization results in increased surface area and improves vaporization.

We have also developed an aerospace-qualified intelligent electronic propulsion management system that provides a range of built-in UAV-specific functionality including anti-stall, power management, speed control and engine protection.

Our engines are designed to provide highly efficient and reliable combustion of a range of heavy fuels including JP5, JP-8 and Jet-A1, allowing them to satisfy single-fuel policies that are currently being enacted by many defense forces around the world today. All Orbital heavy fuel engines are also able to run on gasoline, making them highly versatile.

Production Engines

HFDI.50

Compact 3.6 hp HFE propulsion system for small UAV airframes

The HFDI.50 is a compact two-stroke heavy fuel engine designed to be easily integrated into small UAV airframes. Weighing just 3 kg and delivering 3.6 hp, it can run on JP5, JP8, Jet A, Jet A1, or gasoline with no re-tuning required across the entire altitude range. The engine’s 340 g/kWh cruise efficiency and 500-hour TBO enable longer missions, greater payload flexibility, and reduced downtime.

The HFDI.50 is a compact two-stroke heavy fuel engine designed to be easily integrated into small UAV airframes. Weighing just 3 kg and delivering 3.6 hp, it can run on JP5, JP8, Jet A, Jet A1, or gasoline with no re-tuning required across the entire altitude range. The engine’s 340 g/kWh cruise efficiency and 500-hour TBO enable longer missions, greater payload flexibility, and reduced downtime.

The real-world capabilities of the HFDI.50 have been rigorously proven, with over 250,000 service hours in the field. It is optimized to ensure low acoustic and thermal signatures, and starts reliably in environments from -30°C to +55°C.

HFDI.75

Proven 5.1 hp HFE propulsion system for long-endurance operations

The HFDI.75 is a two-stroke heavy-fuel propulsion system that has been designed with long endurance and mission reliability foremost in mind. Delivering 5.1 hp at just 7.8 kg in weight, it has been proven in multiple active military deployments with over 700,000 operational flight hours worldwide.

The HFDI.75 is a two-stroke heavy-fuel propulsion system that has been designed with long endurance and mission reliability foremost in mind. Delivering 5.1 hp at just 7.8 kg in weight, it has been proven in multiple active military deployments with over 700,000 operational flight hours worldwide.

Featuring built-in ECU and PMU, pumps, wiring harness, engine mounts and propeller, the HFDI.75 enables plug-and-play integration into a variety of airframes. Cold starting is assured at temperatures of down to –30°C, and the engine can run on JP5, JP8, Jet A, Jet A1, or gasoline with no re-tuning.

HFDI-150

Twin-boxer HFE UAV engine with 11.9 hp output

The HFDI-150 is a twin-cylinder two-stroke heavy-fuel engine featuring a horizontally-opposed design. Weighing 10.4 kg, the MIL-STD-810H qualified engine can deliver 11.9 hp with ultra-smooth low-vibration performance.

The HFDI-150 is a twin-cylinder two-stroke heavy-fuel engine featuring a horizontally-opposed design. Weighing 10.4 kg, the MIL-STD-810H qualified engine can deliver 11.9 hp with ultra-smooth low-vibration performance.

The robust engine has completed multiple 3x 150-hour FAR33.49b durability tests and 500-hour mission profile durability tests. It has been selected for Textron Systems’ Aerosonde MK4.8, a tactical hybrid VTOL UAS that has been purpose-built to meet the U.S. Army’s Future Vertical Lift requirements, and has been proven with 25,000 operational hours in the field.

HFDI-350

28.4 hp twin-boxer HFE engine for heavy-lift and long-endurance missions

The HFDI-350 is a two-stroke twin-boxer heavy-fuel engine that has been designed to meet the requirements of heavy-lift and long-endurance Group 3 UAV operations in highly challenging environments, delivering 28.4 hp with low levels of vibration.

The HFDI-350 is a two-stroke twin-boxer heavy-fuel engine that has been designed to meet the requirements of heavy-lift and long-endurance Group 3 UAV operations in highly challenging environments, delivering 28.4 hp with low levels of vibration.

The MIL-STD-810H qualified engine offers high levels of onboard electrical power to support advanced sensors, communications systems and edge computing equipment.

More information: Heavy fuel UAV engines

Custom Propulsion System Development

We work closely with clients to deliver bespoke engine solutions that meet your unique requirements for UAV propulsion. The process begins with an expert consultation to understand and characterize your needs, and we then handle the entire project lifecycle including design, development, testing, and delivery.

We work closely with clients to deliver bespoke engine solutions that meet your unique requirements for UAV propulsion. The process begins with an expert consultation to understand and characterize your needs, and we then handle the entire project lifecycle including design, development, testing, and delivery.

Our facilities in Perth, Western Australia, and Oregon, USA, provide world-class capabilities in design, embedded electronic control, manufacturing and development, as well as comprehensive testing with highly accurate simulation of a wide range of real-world operational conditions.

Key test, development and production capabilities include:

- Multiple engine test cells at each facility

- In-house machine shop

- Altitude simulation chamber with capability to 20,000ft; with temperature control to -35oC to 65oC

- Semi-anechoic NVH room for noise assessments

- Environment Stress Screening including HALT and HASS with simultaneous temperature and vibration

- Comprehensive metrology department

- Annual throughput capacity of 600+ new-build or MRO units at Australian facility & 240+ at US facility

Reviews

There are no reviews yet.